.

.

Building System

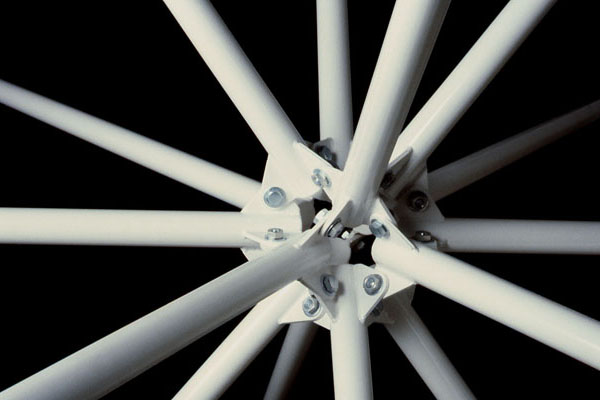

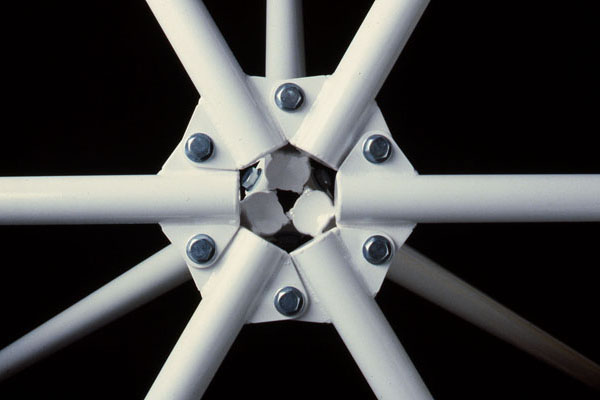

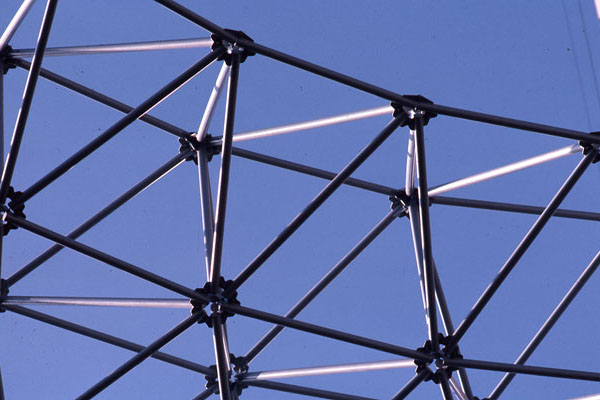

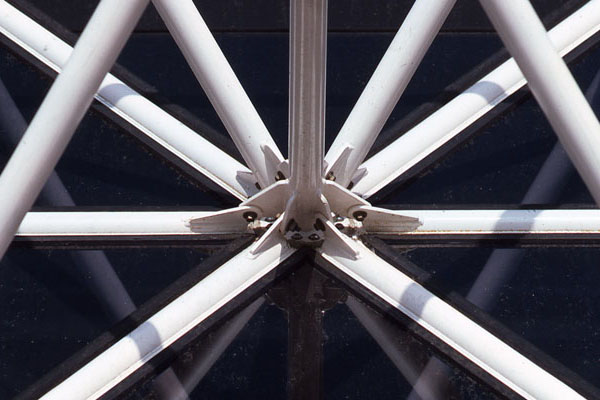

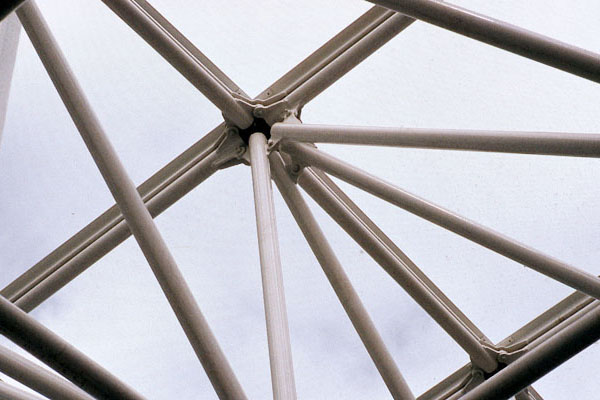

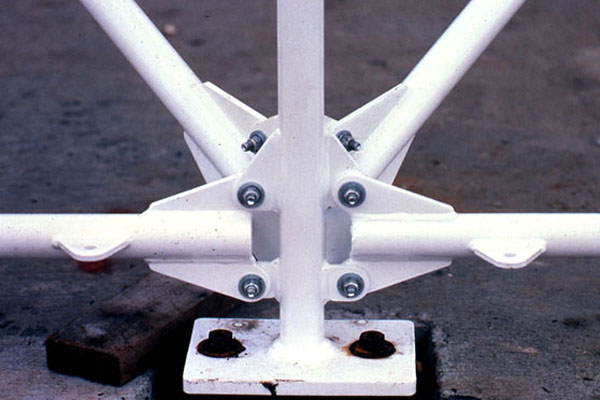

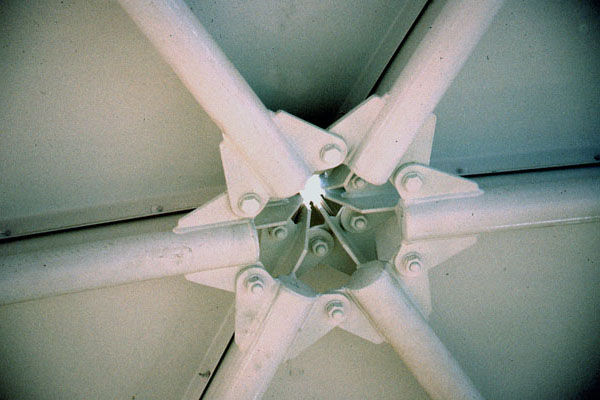

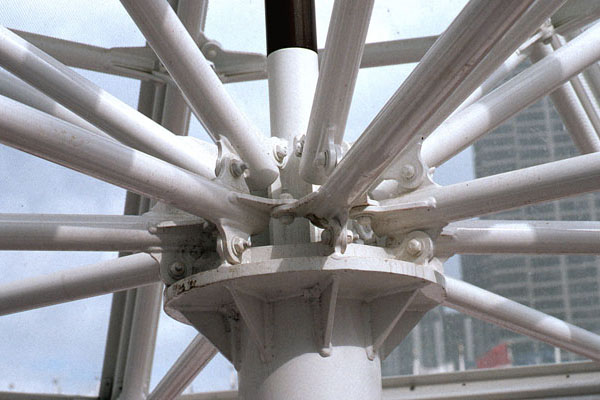

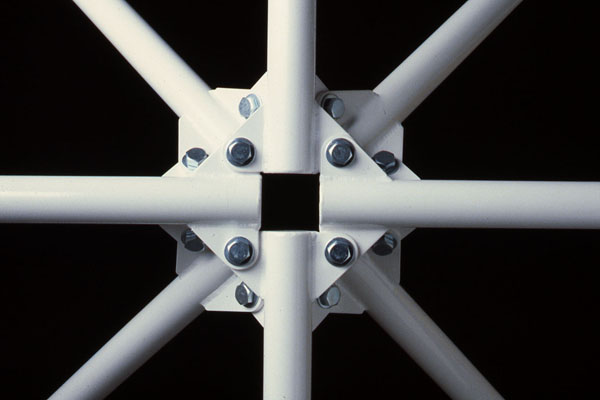

Multihinge Connection System

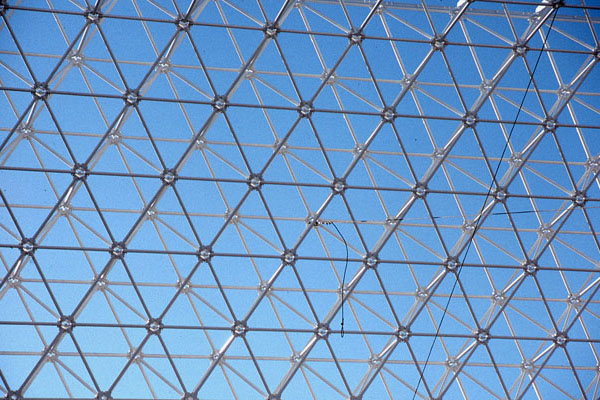

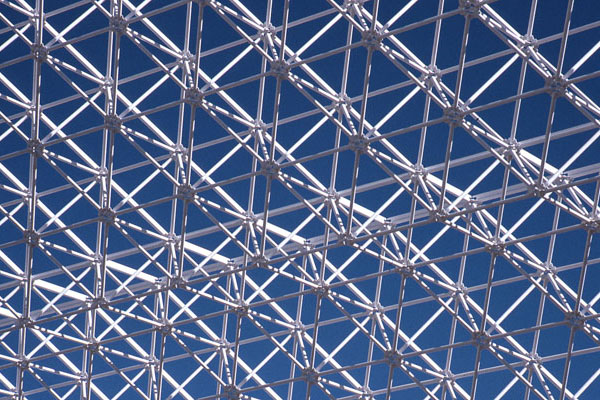

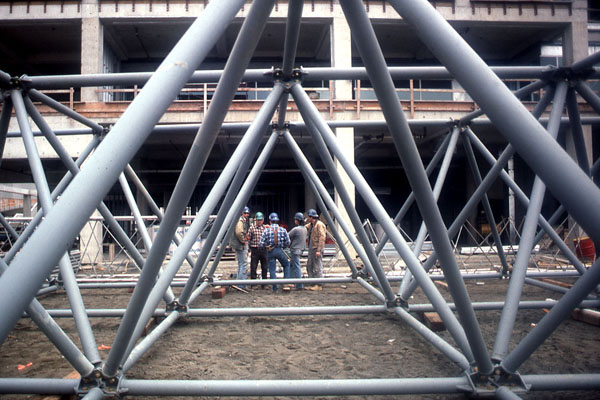

During the mid-1970’s, Peter Pearce developed a theoretical breakthrough as the basis for the design of space truss joining systems. This theoretical system comprises the principles for the design of a nodeless joint system of great inherent performance and manufacturing advantage, known as the Multihinge connection system. This joining system links tubular strut components together in simple ways to form complex high-performance structures. The validity of this concept has been demonstrated through its wide use over a 15-year period from 1980 to 1995.

Pearce Structures, Inc. was founded in the early 1980’s as a design-build company supplying design, engineering, manufacturing, and installation of architectural scale projects based on the Multihinge System. For the next 15 years, Pearce Structures focused upon space truss applications, and integral glazing and cladding systems. During this period, over 80 projects were completed enclosing nearly 2,000,000 square feet of surface area, using the Multihinge Connection System. Pearce Structures terminated operations in the mid-1990’s.

During the period of the early 1990’s, the number of companies providing space frame products increased, and at the same time, the market size began to shrink. Indeed, during the heydays of the post-modern and deconstruction movements in architecture, there was diminished interest in high-performance structural solutions. These patterns resulted in a smaller share of a smaller market, a market that was small, to begin with. Because of this, it was not possible to maintain a level of sales necessary to sustain an integrated design and manufacturing company dedicated to high-performance space enclosure systems. By the end of 1994 Pearce Structures, now called Pearce Systems International, was unable to survive. The Company subsequently closed its doors.

The innovative Multihinge connection is a highly versatile system that can be readily adapted to architectural structures of almost any scale and geometry. It has also enabled the integration of glazing and cladding systems with the structural system to create a total systems approach to the creation of building envelopes.